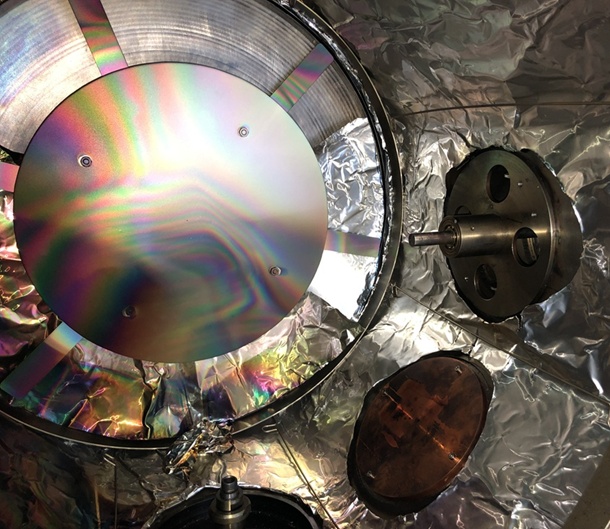

Vacuum Measurement Assembly

UHV gauges integration, calibration, data acquisition and visualization.

We design and deliver pressure‑measurement systems, solutions for energy, semiconductors & clean rooms, and cryogenics – including dewar vessels, cold traps, and cryo pumps. Project management from concept to series.

We are an engineering company focused on customer‑specific solutions in vacuum and cryogenics. We combine in‑house development, precision manufacturing, and rigorous verification. We execute projects in regulated environments with documentation discipline and full traceability.

Requirements, simulation, prototyping, qualification, and serial production – with unified project governance.

Material certificates, measurement protocols, inspection plans. Full traceability of critical parameters.

We deliver complete systems and modules. We integrate sensors, valves, control electronics, cryogenic components, and vacuum assemblies into functional units.

Selection and integration of Pirani / Penning / capacitance gauges, calibration, data acquisition, helium leak testing.

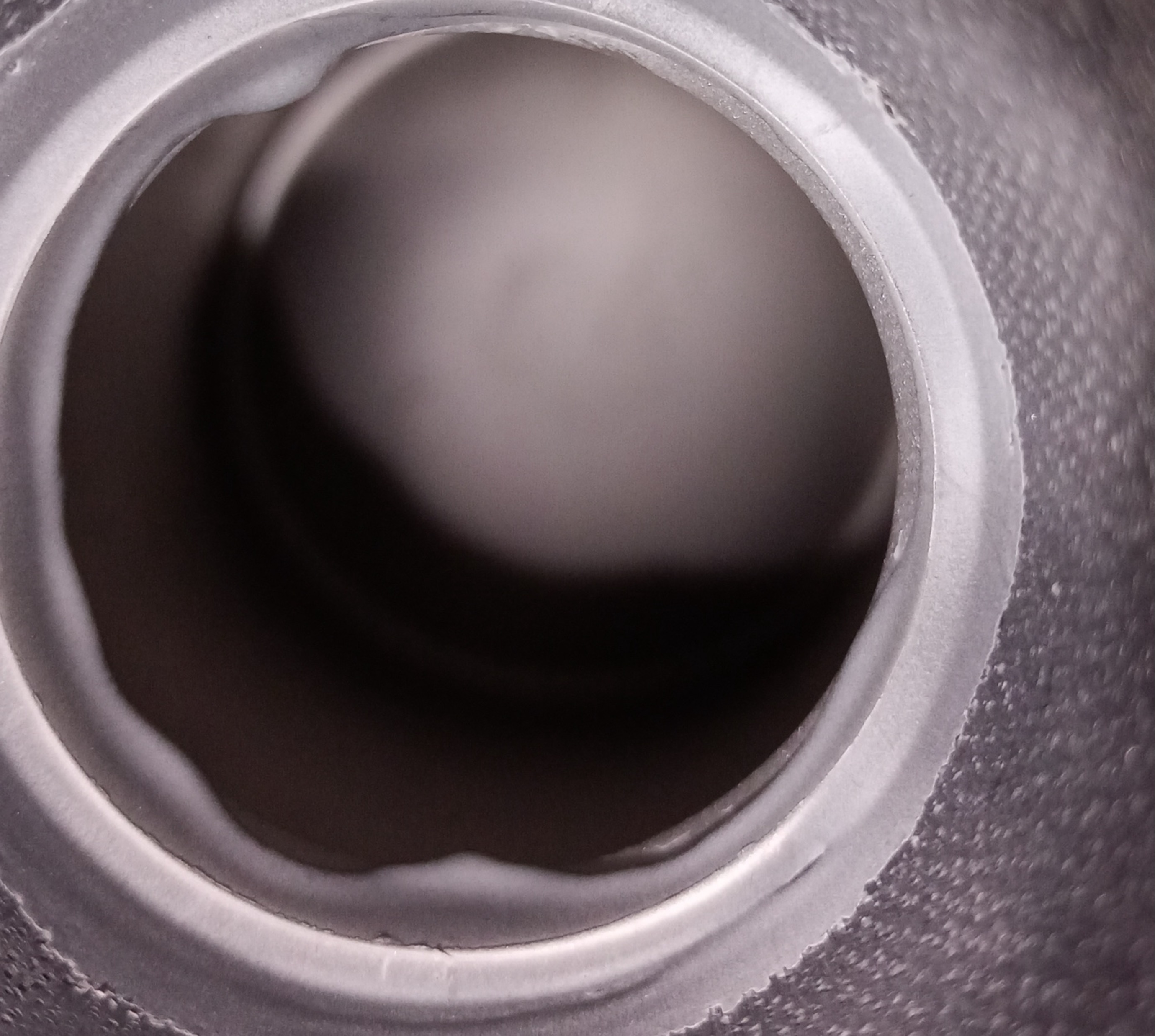

Vacuum chambers and piping for energy applications, filtration, high‑vacuum sections, monitoring and safety components.

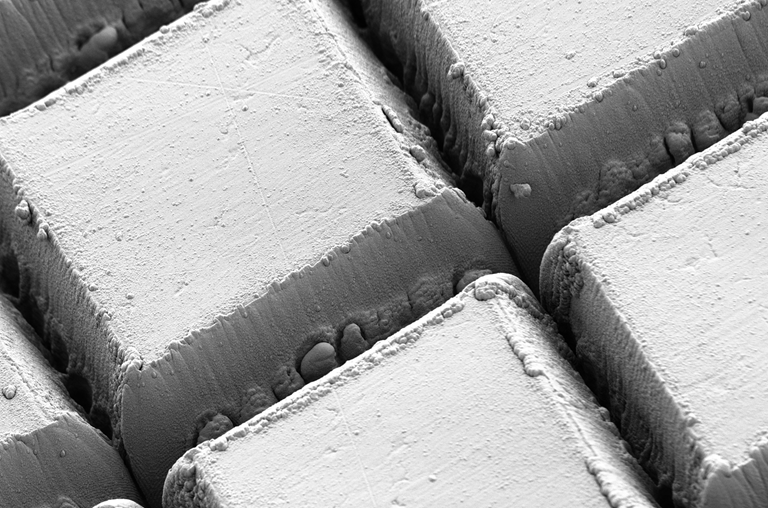

ISO 7 clean‑room compatible assemblies, UHV components, material compatibility, cleanability, and design per industry standards.

Dewar vessels, cold traps, and cryo pumps including thermal management design and safe operating regimes.

Precision EBW of stainless steels and specialty alloys for vacuum and cryogenic applications. Process development, fixturing, and qualification.

We focus on high value‑add projects where technical detail, stable quality, and on‑time delivery are decisive.

Short showcases – technical details under NDA.

UHV gauges integration, calibration, data acquisition and visualization.

Highly efficient adsorption design for stable ultra-high vacuum performance.

Modular transport dewar design with exceptionally low evaporation rate.

Highly specialized UHV chambers tailored for plasma deposition, energy applications and advanced cryogenic processes.

Updates from our LinkedIn – projects, milestones and behind-the-scenes from ALFAVAC.

We take sustainability pragmatically: efficient technologies, responsible manufacturing, and transparent metrics.

Preference for high‑efficiency vacuum/cryogenic components, heat recovery, and smart control. Goal: lower consumption with higher process stability.

Separated collection of stainless and non‑ferrous metals, minimized packaging and paper (digital documentation).

Optimized material flow and shipments, consolidation, and local sourcing whenever it makes sense.

We continuously evaluate key indicators and can share project‑level sustainability metrics on request.

ALFAVAC s.r.o. delivers tailored engineering and manufacturing solutions for the vacuum, cryogenics, and semiconductor industries.

Precision machining, vacuum assemblies, electron‑beam welding (EBW), TIG orbital welding, pressure‑/leak‑testing, and functional testing.

Material certificates, measurement protocols, serial‑number traceability, and controlled documentation for regulated industries.

Design for vacuum/cryogenic operation, thermal modelling, fixtures and tooling for EBW and clean‑room assembly.

From inquiry to series: schedules, milestones, PPAP/FAI on request, and clear communication throughout.

Quick inquiry or technical question? We respond within one business day.

ALFAVAC s.r.o.

Klejnarská 92, 280 02 Kolín, Czech Republic

Reg. No.: 19382278

E‑mail: info@alfavac.cz